Every day isn’t working on a show. There are days set aside for other tasks, and today is one of those. Today is a prep day, and I will be working on the lighting/electric crew today. Usually I work on the audio crew, but if you spend enough time in this business you learn to diversify in order to keep the paychecks flowing. So a lot of techs learn many skills whether they want to or not.

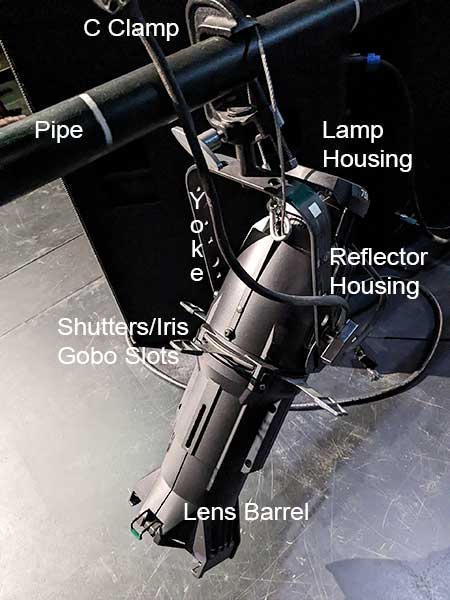

Today should be an easy day, we start off by striking (taking down) some lighting fixtures and cables. Mostly ellipsoidal (Leko) lights, a workhorse in lighting – especially in theater.

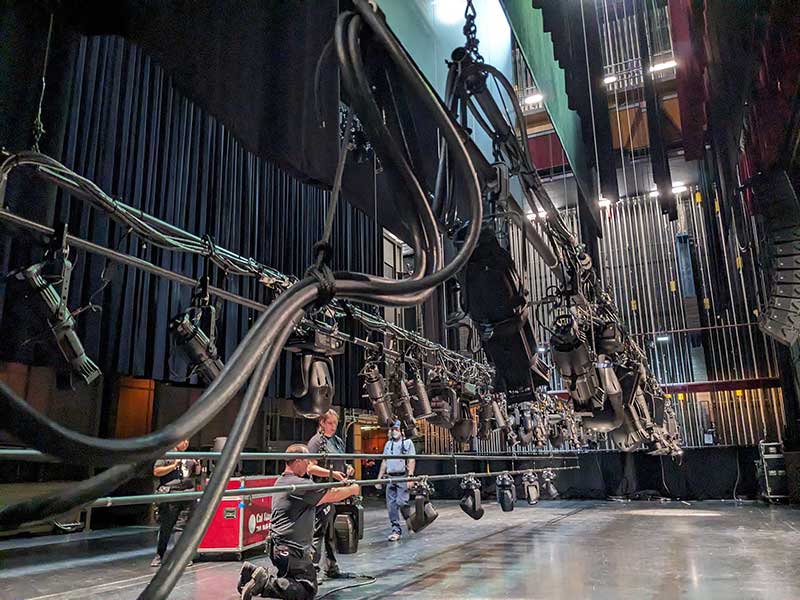

We unplug power and data cables and then untie them from the linesets, then remove all the lighting fixtures hung on the (battens) pipes for storage on “Meatracks”.

In the foreground of the picture above you can see the thick Socapex cables hanging off the end of the pipe. These cables carry multiple circuits of power for lighting fixtures so they are made out of a lot of copper and thick non-conductive outer casing. They hang from the grid at the top of the flyhouse and we usually keep them coiled up on our midrail which we call the 42ft Level. They need to be pulled up and down that 42 feet whenever they are used, have to move or be stored. They connect to stage pin (Bates) cable through “Breakouts”. (photo above) Those cables then can be split with 2-fers or converted to other types of connectors for moving lights etc.

Aside from Par Cans

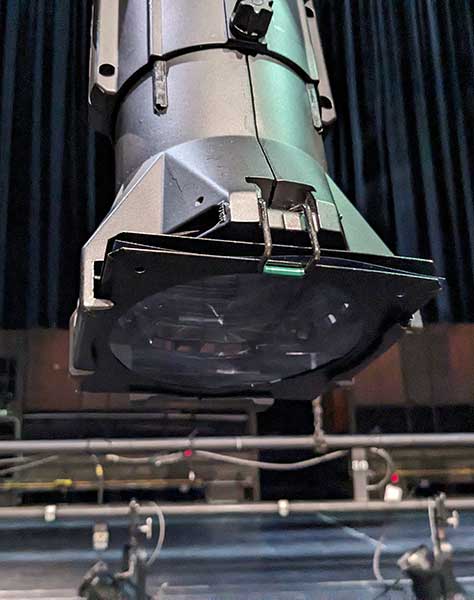

and Ellipsoidal (Leko) lights, we will also remove or move some larger moving lights to use on the next show or be stored.

We also have to collect and distribute small accessories for some fixtures. Things like “top hats”, for lighting control on the front of Leko’s, gels for coloring/softening/color correction on conventional lighting fixtures, gobo patterns for creating shadows.

Par 64 cans.

AND MOST IMPORTANTLY SAFETY CABLES.

Many fixtures will be coming out of a box where they have been stored, as such will have to have pipe clamps re-attached to them so they can be hung on the battens.

We need to scavenge some Baby Colors from the aluminum truss in the shop.

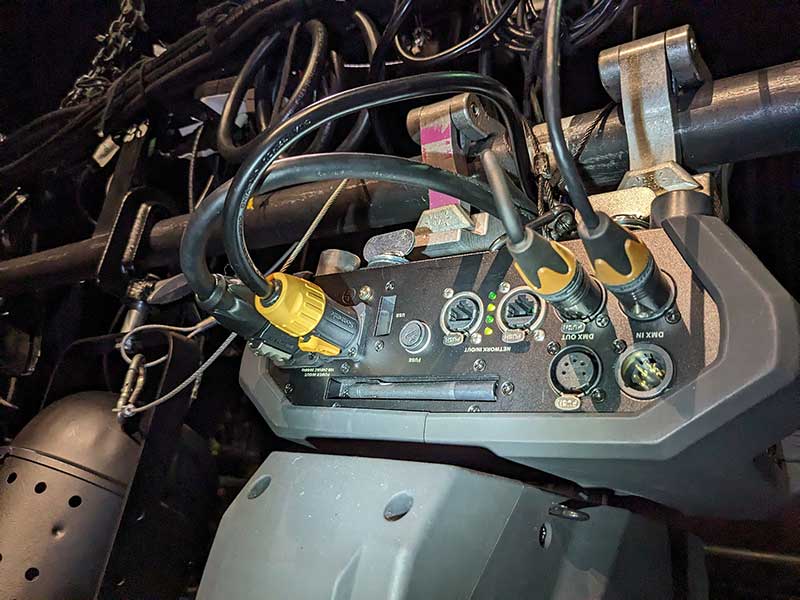

Moving lights don’t work unless they are connected by DMX cables (or network) so there is a lot of DMX cables that have to be run out to each light. And don’t forget about power. After leaving the Socapex, power is converted to Stage Pin / PowerCon or whatever is needed for a particular fixture.

There’s 5 pin and also 3 pin DMX which can be converted between the two but are definitely NOT XLR cables which are for audio.

At the end of the moving lights DMX cable chain don’t forget to put a terminator on the last data output or things may not work as expected.

The moving lights are each assigned a unique address on the network, some lights have dip switches, this one is a little bit more modern.

Once all the old lighting fixtures are removed, the new ones hung, all the cables stripped and then re-hung for the new placement of everything and all the DMX, Power cables, breakouts, and Soccapex are in place and tied up neatly we can tie on a short border to the front of the batten in order to make sure the pipe and cables go unnoticed by the audience during the show. Like everything in this black hole it should be invisible.

Now that everything is connected and looks beautiful it’s time for the carpentry crew do do their thing. A loader at the top of the flyhouse on the loading bridge (82 foot level) will add or remove steel bricks (the same kind as in the upcoming video). The weight of all the lights, cables, accessories, borders etc. will be calculated by the flyperson (in our case here today Alma), at that time the loader will be told how many bricks are equal to (or very close) to that weight and the loader will place steel bricks on the arbor (a carriage) to counterweight the load on the batten (pipe pictured above). Then the flyperson working at the Rail will pull the batten “out”, which to most people means up!

All the lights are hanging in the air! So I guess were done? Nope, now it’s time to build booms! We are lucky to have rolling boom bases which we can build light trees on and then roll where we need them, very convenient.

Each of the rolling boom bases will be loaded with 24, 22 pound steel bricks. The same type of bricks which the loader on the loading bridge uses to counterweight the fly system.

Pipes, pipe clamps, lighting fixtures and cables are gathered together to be hung on the rolling boom bases using the scissor lift and a ladder.

Fixed Cheeseboro (“cheeseburger”) clamps are used to attach horizontal pipes to the tall vertical pipe (upright). The lighting fixtures will hang from these horizontal pipes.

Everybody on the lighting crew today pitches in to build the rolling booms.

Once the booms are built, all the lights are hung and secured and have been cabled with power runs and data to their bases, power cables are pulled from the floor trough in order to route power and data to the fixtures on the booms from below. Then the ME/LD can test the setup from the onstage control wing of the lighting desk.

It’s a short day so it’s time to clean up now. Here is a view looking up at the Socapex cables hanging from the 42 level and above at 85 feet, the big yellow thing is our grid from which everything hangs in the flyhouse.